Proudly Made in the U.S.A.

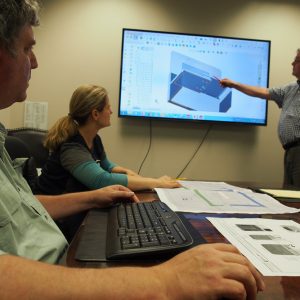

Located in Auburn, Washington, 20 minutes south of Sea-Tac International Airport our facility includes 5 buildings totaling 100,000 square feet on 7 acres. Our dedication to customer satisfaction and industry-leading processes has kept clients coming to us for over 60 years. Combining state of the art software with the latest CNC machines available, we can implement your designs and create projects that most people only dream about.